UNEARTHED

As a diamond consumer, you’ve probably heard that diamond is a dense polymorph of carbon. But have you ever wondered about the journey of a lab-grown diamond, from its humble beginnings as carbon molecules to its dazzling presence in jewelry stores? Today, we’re taking a deep dive into the fascinating world of LGDs. So, without further ado, grab your lab coat and let’s explore the science behind these marvels of modern engineering.

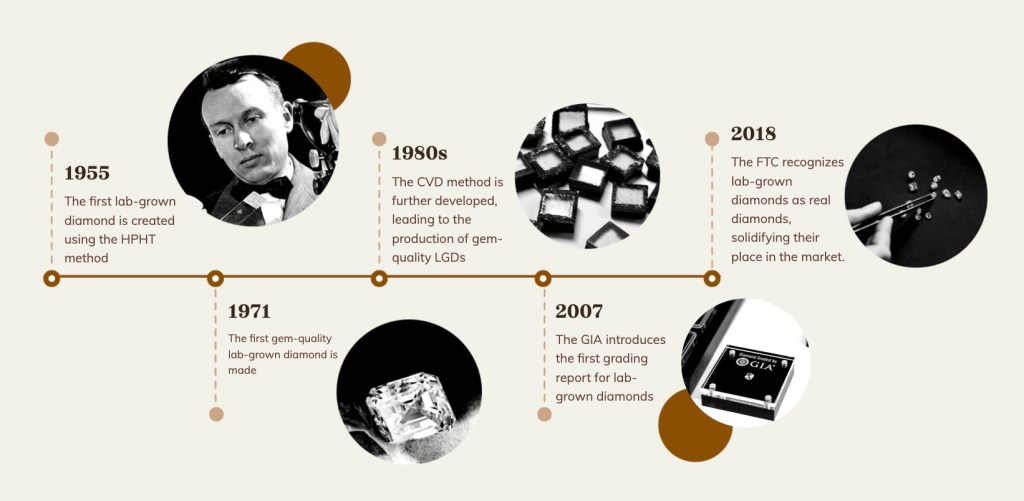

Timeline of Lab-Grown Diamonds

Let’s start our journey by tracing the history of lab-grown diamonds.

Understanding Lab-Grown Diamonds

Before we delve into the nitty-gritty of how lab-grown diamonds are made, let’s first establish what they are. At their core, lab-grown diamonds replicate the formation process of mined diamonds in a lab and are made from the same mineral, carbon.

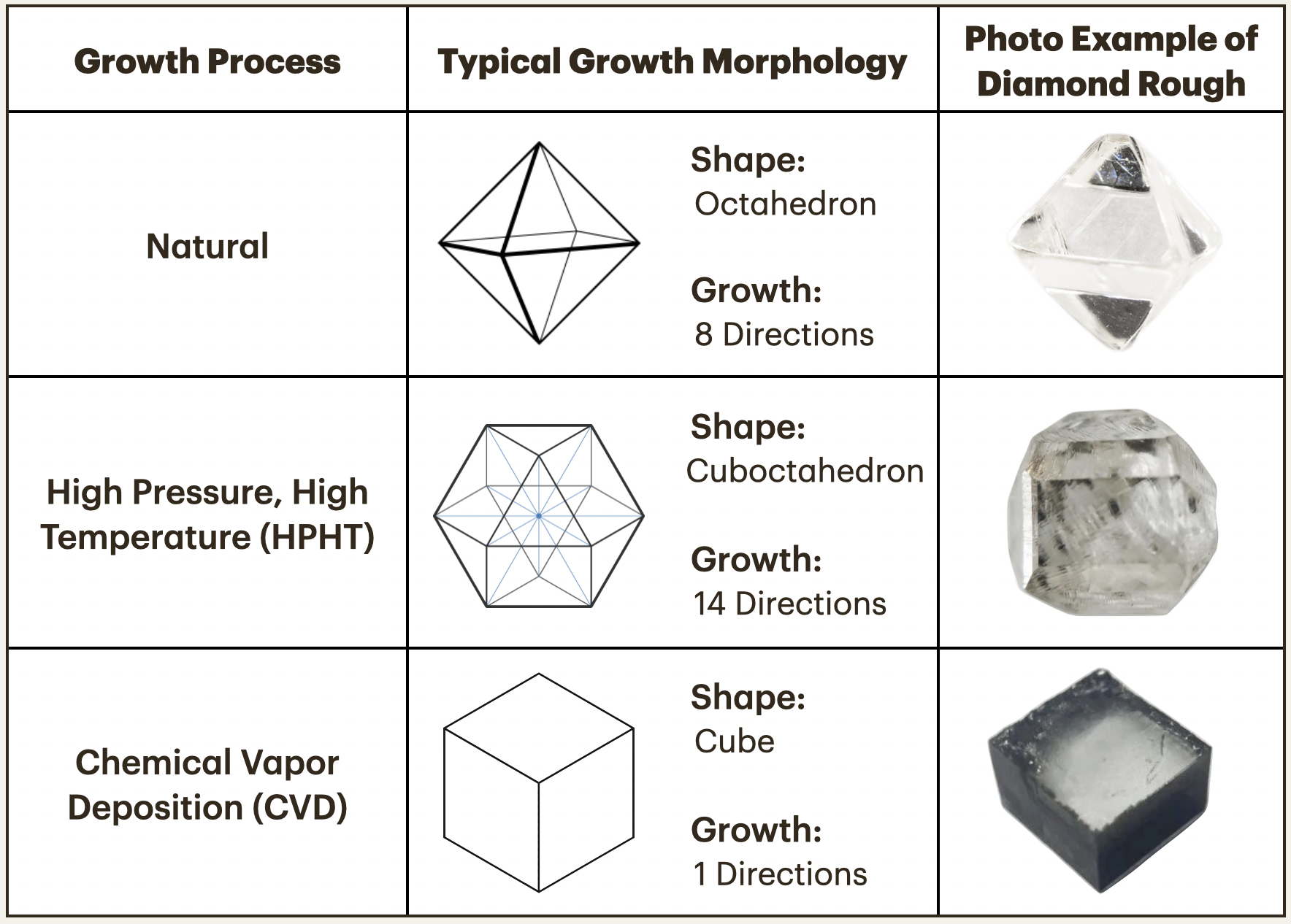

Today, lab-grown diamonds are produced by two methods primarily: chemical vapor deposition (CVD) or high pressure, high temperature (HPHT).

Now that LGDs are everywhere, how do we choose? Which lab growing method is best? Don’t worry! We will discuss how HPHT and CVD diamonds are alike and dissimilar, as well as provide you with some tips on how to choose the right diamond for your needs.

HPHT Method: A Diamond in the Rough

The journey of lab-grown diamonds began in 1955, when scientists at the General Electric Research Laboratory achieved something close to alchemy. Scientist Robert H. Wentorf bought a jar of peanut butter, brought it into his lab, and then turned a glob of the bread-spread into a few tiny diamonds. The trick to making diamonds from peanut butter, or, more reasonably, from graphite—diamond’s all-carbon mineralogic sister—lay in recreating a similar environment that produces diamond deep within the earth’s mantle. This groundbreaking discovery laid the foundation for the High Pressure High Temperature (HPHT) method.

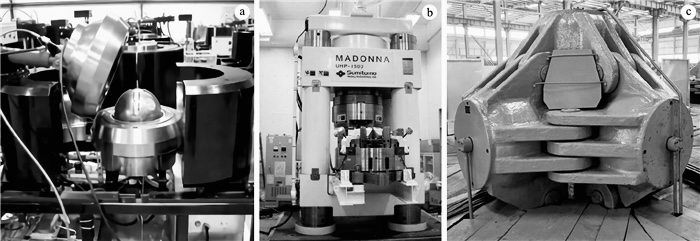

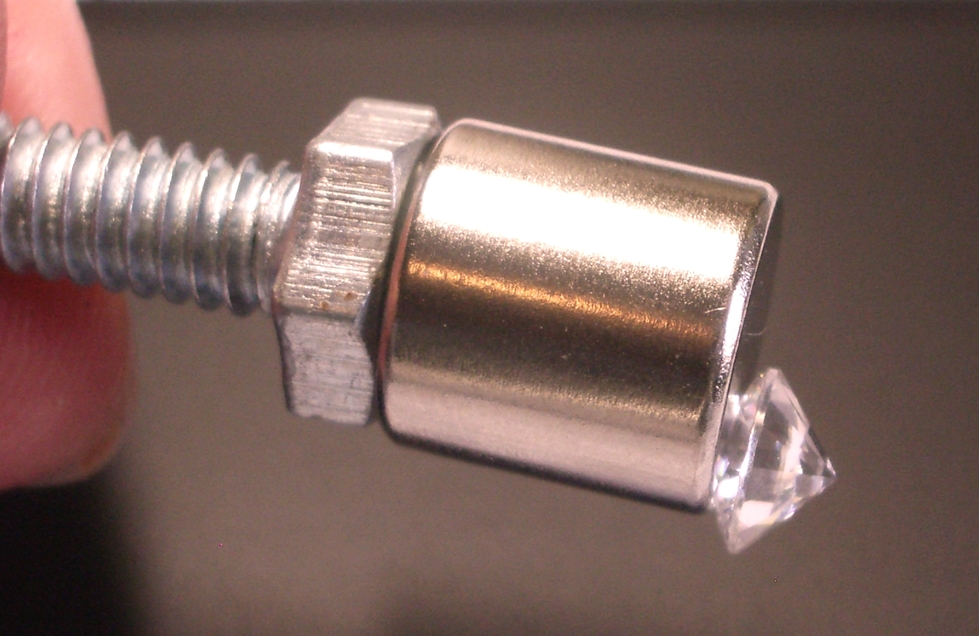

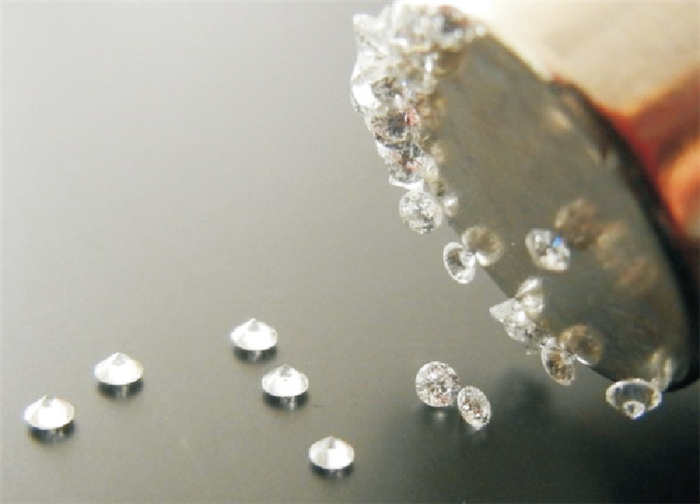

In the HPHT process, a diamond seed plate serves as the foundation for growth within a chamber containing pure carbon powder dissolved in a molten metal flux mixture. Catalyst metals such as nickel, cobalt, or iron are added to expedite the growth process. The chamber is then subjected to extreme temperature and pressure (up to 1700°C and 6.5 GPa). As the mixture cools down, the carbon crystallizes onto the seed plate, resulting in the formation of a diamond.

While successful, the HPHT method may produce diamonds with slight colorations and imperfections. Some may have a yellow hue since they are often exposed to nitrogen while others may have a blue hue from boron exposure. Additionally, metallic inclusions can occur, making some diamonds magnetic—a distinguishing feature of HPHT-grown diamonds. Study results found that 85% of HPHT diamonds over a half carat were magnetically detectable. So while not a smoking gun, magnetism is a good test if trying to identify a HPHT diamond.

CVD Method: Diamonds from Thin Air

Chemical Vapor Deposition (CVD) grown diamond is another fascinating innovation in the diamond industry. Invented in the 1950s and refined in the 1980s to produce gem-quality diamonds, CVD has been commercially viable for about 15 years. In this process, carbon-containing gases, such as methane, decompose under intense heat within a vacuum chamber, depositing carbon atoms onto target surfaces to form the layers of a diamond.

CVD diamond quality varies, depending largely on the amount of time growers take to nurture their diamond rough and how well they’ve fine-tuned the “recipes” (check out this cool at-home diamond growing experiment). In comparison to the HPHT method, CVD offers a more versatile approach: allowing for the faster growth of larger diamonds. De Beers’ lab-grown diamond brand—Lightbox—for instance, leverages the CVD technique to grow their diamonds, with an annual output of rough diamonds about 200,000 carats.

HPHT vs. CVD — Which Is Better?

The two growth methods for producing lab diamonds, HPHT and CVD, are significantly different from one another, leading to variations in certain quality factors unique to lab-grown diamonds. It’s important to note that both methods are capable of producing outstanding quality diamonds.

HPHT growth can reliably produce very pure, transparent diamonds without the need for any secondary treatments. This is because an HPHT diamond grows in 14 different directions, enhancing its ability to refract light, whereas a CVD diamond grows only in one direction. Many CVD diamonds thereby require post-growth treatments to mitigate issues arising from the growth process. In fact, labs often use the HPHT process on CVD diamonds after growth to further enhance their quality.

One advantage of CVD diamonds is their affordability compared to HPHT diamonds. This is because CVD growth is conducted in smaller and more affordable reactors relative to HPHT presses, making CVD diamonds easier to scale and more widely available.

Which One Should You Get, HPHT or CVD Diamond?

Now that you understand the difference between HPHT and CVD, it’s time to decide which one is right for you. Here are a few factors to consider when you’re ready to go looking:

| HPHT Diamonds | CVD Diamonds | Why? | |

|---|---|---|---|

| Budget | ✔ | CVD diamonds tend to be less expensive than HPHT diamonds. | |

| Quality | ✔ | HPHT diamonds tend to be of a higher quality than CVD diamonds. | |

| Size | ✔ | CVD diamonds are often easier to produce in larger sizes. | |

| Availability | ✔ | CVD diamonds are more widely available compared to HPHT diamonds. |

Ultimately, the choice between the two methods depends on individual preferences and priorities. We are of the mind that if you find a lab diamond you like, go for it no matter how it was grown.

Conclusion

Lab-grown diamonds are rapidly becoming a mainstream part of the jewelry industry. While diamonds were first created in the lab in the 1950s for industrial uses, it’s only in recent years that gem-quality diamonds have become commercially available. Consumer interest in lab-grown diamonds has surged as prices for high-quality diamonds have become more affordable.

Two predominant methods of growing diamonds—HPHT and CVD—now dominate the industry. Each method has its unique process and characteristics, contributing to the production of high-quality diamonds. Despite some defects that may require post-growth treatment, both methods play a crucial role in meeting the growing demand for lab-grown diamonds.

As we wrap up our journey into the science behind lab-grown diamonds, it’s evident that these gems represent more than just beauty—they embody innovation and progress. With their growing presence across the globe and the flexibility they enable in terms of experimentation, LGDs are poised to shape the future of the industry. No doubt, this is an extremely exciting and revolutionary time for everyone in our industry and lab-grown diamonds are a huge part of it.

Leave a Reply to Finding the Perfect Engagement Ring Through a Cross-Continental Virtual Appointment – Grit to Gleam Cancel reply